- Nucleic Acid Analysis

- Protein Analysis

- Biochemical Reagents

-

Enzymes

- Thermophilic DNA Polymerases

- Mesophilic DNA Polymerases

- Restriction Endonucleases

- Reverse Transcriptase and RNA Polymerases

- DNA/RNA Ligases

- RNases

- Proteases

- Nucleases

- Kinases

- Phosphatases and Sulfurylases

- DNA Repair Proteins

- Single-Stranded DNA Binding Proteins

- Chaperon Proteins and Disulfide Bond Isomerase

- Others

- Gene editing

- Molecular cloning

- Clinical diagnostics

- Human Identification STR kits

- Laboratory instruments

- Software

- A&A Biotechnology

News

-

1st Czechoslovak Congress of Medical Genetics 2025

In the spring, we will participate in the 1st Czechoslovak Congress of Medical Genetics, which will take place from April 2–4, 2025, at the Cultural and Congress Center Elektra in the spa town of Luha...

Read more -

RANK 2025

Visit us at the 19th edition of the RANK 2025 conference, which will take place on March 19th and 20th at the Zlatá Štika Hotel in Pardubice. The conference is organized by the Czech Society of Clinic...

Read more -

Kapras Day 2025

We would like to invite you to the 23rd Kapras Day on the topic of "Clinical Genetics," which will take place on Wednesday, February 26, 2025, in the Congress Hall of Hotel Olšanka in Prague. We loo...

Read more

Vertical laminar flow cabinets (Laminar flow) are designed for creation of dust free abacterial air environment. They are used for work with low-risk substances and bacterial cultures, for protection of working materials from contaminated environment and for carrying out experiments in sterile working conditions.

Vertical laminar flow cabinets are designed only for protection of products harmless for personnel and the environment.

Application of Laminar flow systém

- quality control in pharmaceutical and food industry

- sterile manipulations

- sterility tests

- ophthalmological solution preparation

- cultural media preparation

- optical mechanics manufacture

- electronics industry

- pharmaceutical industry

The laminar flow cabinet operation is based on forced air ventilation through HEPA superfine fiber filter.

Going through the prefilter, the air is refined from aerogenic impurities, and owing to the excess pressure in the pressure chamber it is moved to the working chamber by unidirectional vertical falling stream through the terminal filter.

From the working area the air is moved back to the environment in the following way: partly – through the perforation in the bottom rear area of the cabinet, but most air – through the space between the working surface of the table and the protecting glass.

The vertical laminar flow cabinets are designed only for product protection.

Distinctive features of Laminar flow

- The fan motor microprocessor control system SintelL-1 allows to minimize the power consumption of the cabinet, to reduce the level of acoustic and electromagnetic noise.

- The system of air consumption static regulation AIS LS automatically regulates air balance in the working chamber, changing the number of fan revolutions according to the level of filters contamination. Reaching the threshold value of contamination the system activates the warning system.

- The electronic shield panel provides easy operation and disinfection.

- All electric control systems are not placed in the main working chamber.

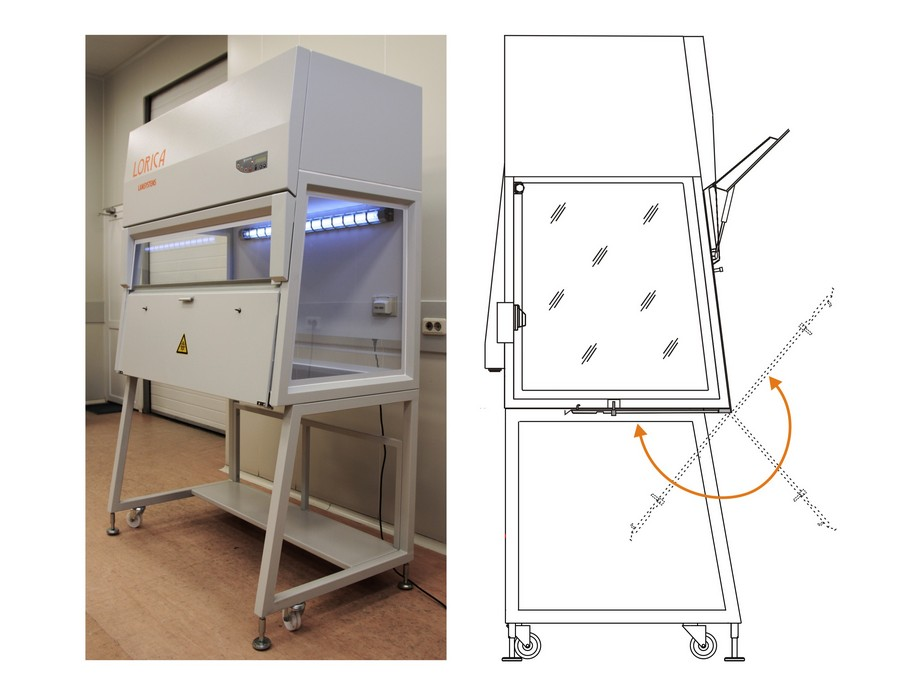

- The window rising mechanism allows fixing window in two positions which makes the working chamber and the window easy to clean from both sides with disinfectant solutions.

- The illumination block is taken out of the working chamber and does not initiate air flow turbulence.

- Coloring of the cabinet is made with the powder enamel proof for the whole lifetime.

- HEPA filter is held by springs providing filter leak tightness for the whole lifetime.

- The control unit with LCD display indicates switching on the systems, their possible malfunctions, the operation mode chosen and the technological timer.

MAIN CHARACTERISTICS

|

Air cleanliness class in the working chamber of the cabinet according to ISO 14644-1 |

5 ISO |

|

Class of the installed in the cabinet НЕРА-filters according to EN 1822-1 |

H14 |

|

Prefilter according to EN 779 |

G4 |

|

Air downflow velocity in the working chamber at a distance of 150 mm from filter in every definite point, m/sec |

0.4 |

|

Illuminance level in the working zone, lux, not less than |

1000 |

|

Noise level at 1m distance from the cabinet (at centerline of the work opening with the front window sash at working position), dB, not more than |

55 |

MAIN PARAMETERS AND DIMENSIONS

|

Article |

412.120 – 1,2 m 412.150 – 1,5 m 412.180 – 1,8 m |

|

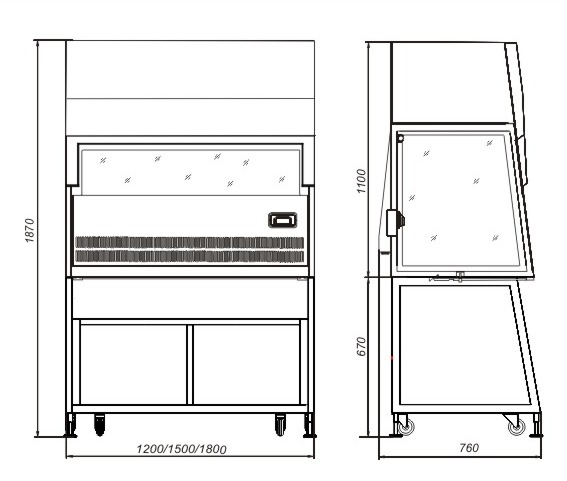

Dimensions of the assembled cabinet with the stand /WхDхH/, mm |

1200х760х1870 1500х760х1870 1800х760х1870

|

|

Dimensions of the working chamber /WхDхH/, mm |

1130х625х650 1430х625х650 1730х625х650 |

|

Mass of assembled cabinet with the stand, kg, not more than |

160/186/206 |

|

Maximum input power of the cabinet, W, not more than (exclusively of the load on the built-in outlet unit) |

410/410/590 |

|

Accepted load on the built-in outlet unit, W/А, not more than |

1000/100 |

PROTECTION PLATE

Acceptable load on the built-in outlet unitThe UV lamp is used for disinfection of the working chamber and its surfaces. Protection plate is provided for operator’s safety.

The protection plate 1 (see picture right) is designed to protect operator from the direct exposure to the UV rays during the disinfection of the working chamber with the UV-irradiation. It is also recommended to apply the protection screen (plate) when the Cabinet is not used for a long time.

Complete information about the use of protection plate is in the OPERATING MANUAL

DIMENSIONAL DRAWING 1,2 m

Cart

Payment gate